Reliability • Schedule Compliance • Cost Efficiency

Construction Engineering

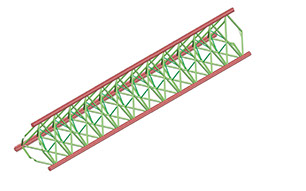

• Construction Engineering

• Project Management

• Raw Materials Sourcing

• Manufacturing/Fabricating

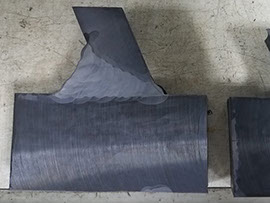

• Heavy fabrication of high-strength steel

• Frame cut and/or machined parts

• Steel forming of pipes, transitions and

other heavy components

• Welding Engineering

• Logistics/Transport

• Assembly/Installation at the shipyard site

• Gear Refurbishment, Recertification and Supply

Let our dedication to quality and precision execution produce the results you want – on time, on budget

and meeting the most rigorous standards – with

No Learning Curves. No Compromises.

No Learning Curves.

No Compromises.

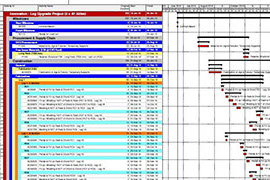

Scheduling & Planning

Welded Rack & Chord Supply

WPSPQR Consulting