Protecting your assets & minimizing downtime

Fast Turnaround

Repairs and upgrades to existing jackup legs are JSA’s day-to-day business.

Fast turnarounds for jackup leg components such as racks, chords, and

bracings are possible due to our extensive steel inventory and fully integrated

manufacturing capability. Our stock materials carry multiple certifications and

include 100 KSI yield plates in thicknesses of 4”, 5”, 6”, 6 1/2”, and 7” which

can be used on virtually any jackup anywhere in the world.

Pipes

Through our quality resource mills in South & North America, Europe, and Asia,

we meet your most stringent chemical and mechanical properties with seamless,

SAW, ERW & HFI pipes to various API 5L and plate grades. Our Jackrabbit plant

has the ability to make small diameter welded pipes as per API, ABS, DNV, etc.

Plates

We fabricate extra high strength, offshore, shipbuilding/hull, boiler/pressure

vessel and structural steel to various International structural steel standards

such as API 2W/2H, EN 10025, EN 10225, and ASTM.

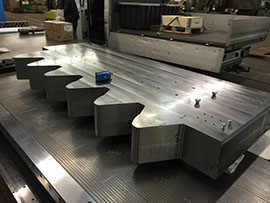

Cut Shapes

Our state-of-the-art steel and flame cutting facilities produce the finest available

heavy parts for the Oil & Gas Industry.

Forming

Roll and Press forming of very large, very heavy parts can be achieved either

hot or cold utilizing some of the largest equipment of its type in the world.

In addition, formed parts can be Quenched & Tempered or Stress-relieved

on site depending on the specification.

Machining

Precision machining can be performed on extremely large structures.

Machining can be performed in our facilities or at the customer's facility.

Repairs & Upgrades

No Learning Curves.

No Compromises.

Formed Chord

Profiling of Bracing Pipes

Rack Chocks